behr a family business with tradition

Internationally focused, constantly innovative, close to our customers and deeply rooted in our location in Düsseldorf for over 65 years.

Historic company milestones of behr Labor-Technik GmbH: |

|

|

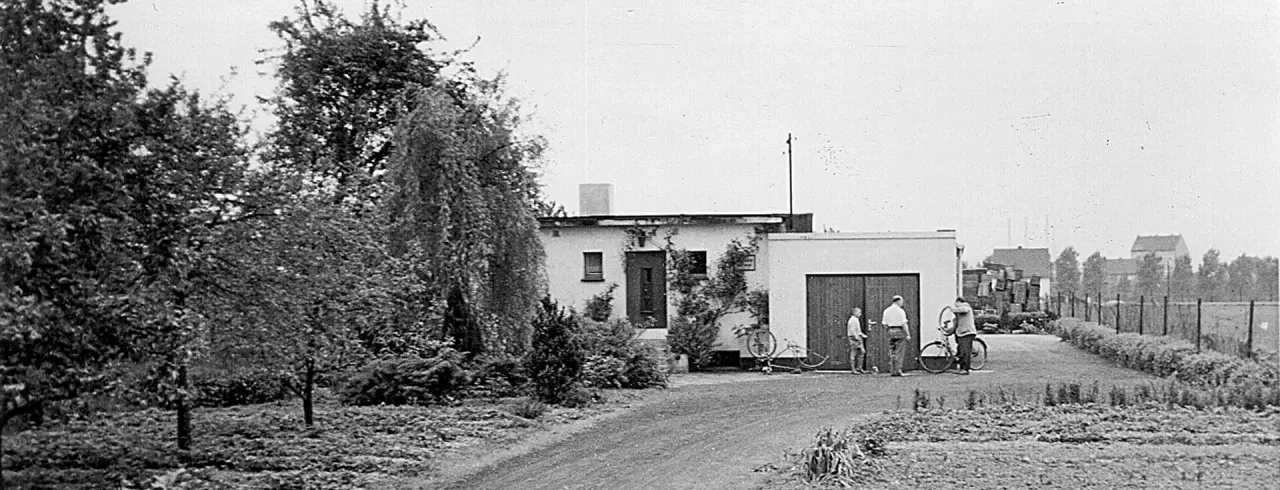

1951 |

Establishment of Franz Behr Laborbedarf [Franz Behr Laboratory Supplies] as a trade business in the field of laboratory devices and supplies. |

|

1960 |

Setup of an in-house glassblowing workshop. |

|

1961 |

Establishment of a workshop for plastics processing and the development of a regeneration station for water inertization. |

|

1970 |

Manufacture of the first hyaluronic® water inertization. |

|

1975 |

Mr. Jürgen Behr joins the company to mark the second generation of the family-run business. |

|

1978 |

behr joins the VGKL ("The association wants to represent and improve the general professional and commercial interests of the wholesale and the foreign trade dealing with nursing and laboratory supplies"). |

|

1981 |

The production of behrotest® devices for environmental and food analysis is launched. Expansion the of service area and customized manufacture in accordance with customer requirements by setting up workshops for electronics and precision engineering. |

|

1988 |

Franz Behr Laborbedarf changes to behr Labor-Technik GmbH. |

|

1995 |

Expansion of the company premises reaching its current size, with training rooms and modern application laboratory. |

|

1997 |

Takeover of the research and development team of Ströhlein GmbH & Co. KG under the management of Prof. Johannes Kupka and establishment of a new business unit: Development and production of devices for elementary analysis (AOX, EOX, POX, AOS, carbon and sulfur determination). |

|

2005 |

The quality management of behr Labor-Technik GmbH is certified in accordance with DIN EN ISO 9001:2008. |

|

|

|

|

2008 |

behr Labor-Technik is awarded the Ökoprofit certificate in 2008. |

|

|

Ökoprofit is a project of the Local Agenda Düsseldorf and an element of the Düsseldorf Climate Protection Program. |

|

|

Ökoprofit is awarded to businesses that increase their resource efficiency, minimize their operative risks, secure their jobs and increase competitiveness, particularly with regard to saving energy and energy efficiency. |

|

|

http://www.duesseldorf.de/oekoprofit/beteiligte_unternehmen/2008/behr.shtml |

|

2013 |

Setup of an in-house export office Longstanding experience in the field of export, annual training on the latest export regulations.Approval as a known consignor by the German Federal Office of Civil Aviation. Service for customers: Import of special goods from abroad, eliminates costs administration of receivables for our customers. |

|

2014 |

Mr. Maurice Behr joins company management to mark the third generation of the family-run business. |

| 2014-2016 |

Modernization and automation of our regeneration system for ion exchangers (mixed-bed resins) pursuant to the latest legal framework conditions Benefits for our customers:

Sustainability:

|