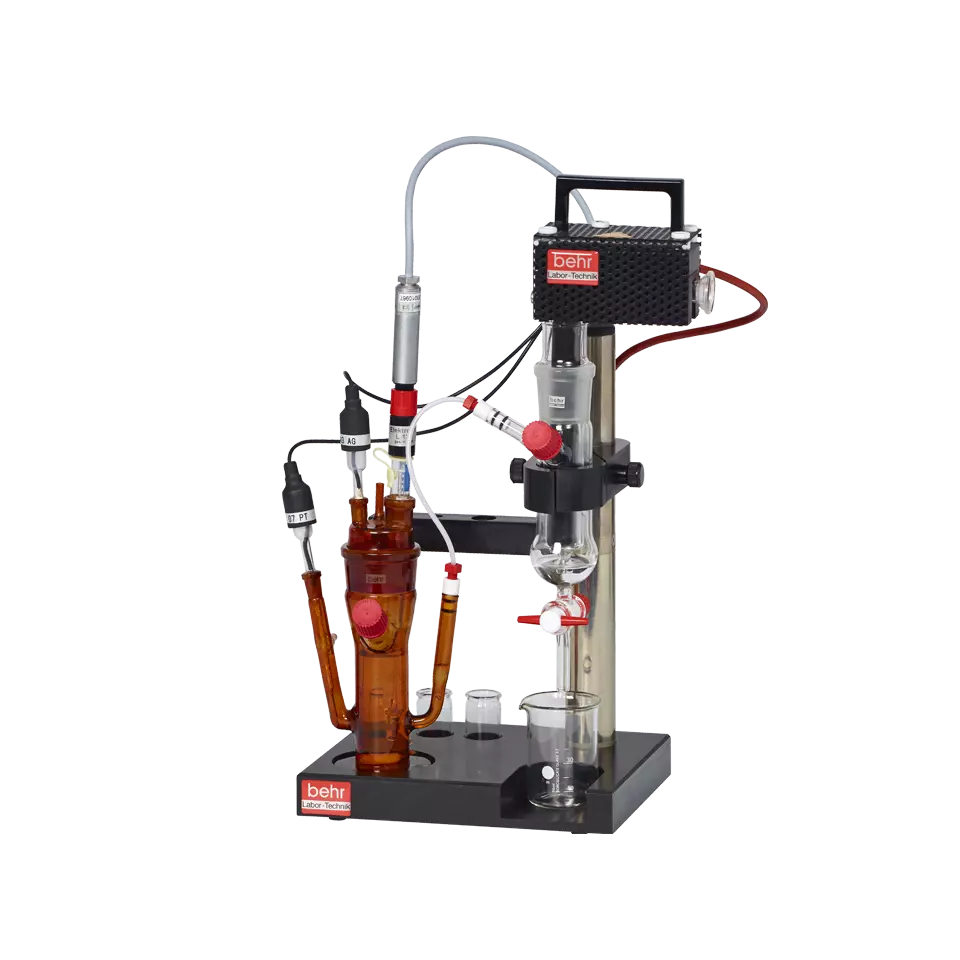

Analyzer

The automatic analysis system behr CL 10 for the coulometric determination of halogen compounds consists of the components: Sample entry module for solid, liquid samples, furnace unit with programmable infrared furnace and downstream resistance furnace with constant temperature, microcoulometric titration unit (optionally tempered and in the casing), control software